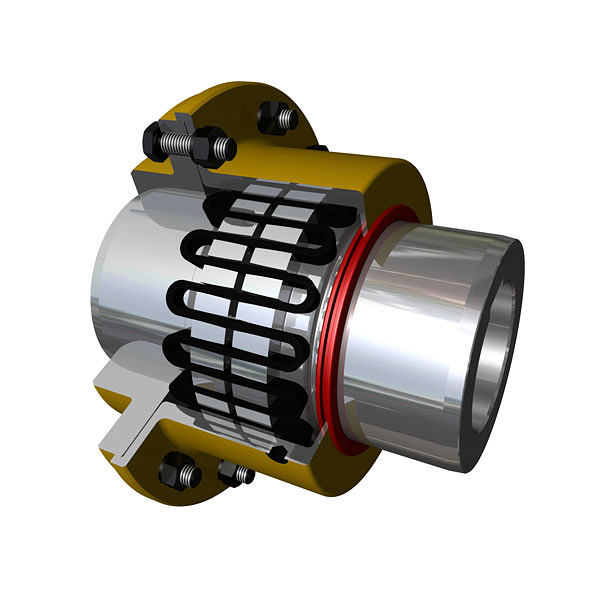

The serpentine spring coupling is a metallic coupling with an advanced structure that relies on a serpentine spring leaf to

transmit torque. It has good vibration damping performance, long service life, large load variation, safe starting, high

transmission efficiency and reliable operation. Although the snake spring coupling has so many features and advantages,

the user should pay attention to the installation of the snake spring coupling. As a manufacturer of serpentine spring

couplings, we propose that the following aspects should be paid attention to during installation and use.

1. Carefully align the installation and control reasonable deviations.

Although the serpentine spring coupling allows a large installation deviation, it should be within the specified value during

installation.

(1) Calibration of the gap and angular deviation between the two couplings. During installation, measure the gap between

the two couplings every 90°. The difference between the maximum value and the minimum value shall not exceed 0.38mm.

(2) Radial deviation correction. Place a ruler on the two-petal coupling, measure every 90°, and check with a ruler. The radial

deviation does not exceed 0.38mm.

2 Choose the right grease

The oil injection point temperature is ≥150°C, can resist centrifugal force, has separation stability, is impurity-free, and does

not corrode carbon steel and nitrile rubber lithium-based grease.

3. Fill with enough grease

Sufficient grease is very important for the operation of the coupling. It is recommended to check it once a year. Use a dry

grease gun to inject grease until excess grease escapes from the hole.

JS Series Snake Spring Coupling Instructions for Use

JS series snake spring couplings include basic type, medium and high speed type, fully unloading type, semi-unloading type,

remote transmission type, brake wheel type, brake disc type, etc. Specification models JS101-JS125 series, torque range

45-800000N.m, allowable speed 4500-540r/min, shaft hole range 14-500mm. The outer diameter of the serpentine spring

coupling housing is 98-1270mm. However, the precautions for use are similar. as follows:

1 Before installing the spring, fill the tooth grooves of the coupling with the specified grease, and then use a mallet to knock

the spring into place. Note: The disconnected ends of the spring should face the same direction to ensure that the cover can

Close up. The two covers are assembled on the same side according to the markings, and they are closed according to the

markings, and then the bolts are tightened. It is absolutely not allowed to tighten the bolts when the two covers are not closed

to avoid damage to the covers.

2. Open the cover, use a round steel or bolt driver to first insert the disconnected end of the spring, pry upward, then insert the

ring-shaped end of the spring, use the inner teeth as a fulcrum, and pry open the springs one by one in the radial direction.

The above is provided by the technical department of Hebei Rongxing Drive Equipment Technology Co., Ltd. The specific technical

parameters of the Snake Spring Coupling can be inquired through the drawing column of this website or free consultation through

the contact information of the website.

Contact: Spark Wang

Phone: 86-19932127135

E-mail: admin@rongxingcoupling.com

Add: North side of Planning 4th Road, Southern Industrial New Town, Jizhou District, Hengshui City, Hebei Province, China